Briefing

TASK

In this campaign, we kindly ask you to identify potential applications for electrically conductive rubber materials across all industries.

SCOPE

We are seeking ideas and proposals that identify system-critical components within a system and are related to our core competencies of material expertise, solution design and operational excellence. Given Datwyler's presence in the B2B sector, our focus is on opportunities that serve the functionality of a system.

BACKGROUND

Datwyler is a leading provider of high-quality, system-critical elastomer components. With recognized core competencies in solution design, material know-how and operational excellence, we are a strategic engineering partner for innovative systems in global markets such as Healthcare, Mobility, Connectivity, General Industry and Food & Beverage. To address arising trends and future market needs in various industries, Datwyler is expanding its in-house capabilities through a focus on Electrically Conductive Materials, which is one of the focuses in the so called ETEMI™. Project ETEMI™ was launched in 2020 to address challenges in various applications, with a material development scope covering all types of conventional elastomers. Now, together with the HYVE community we would like to explore opportunities to apply this material in real life applications.

TECHNOLOGY

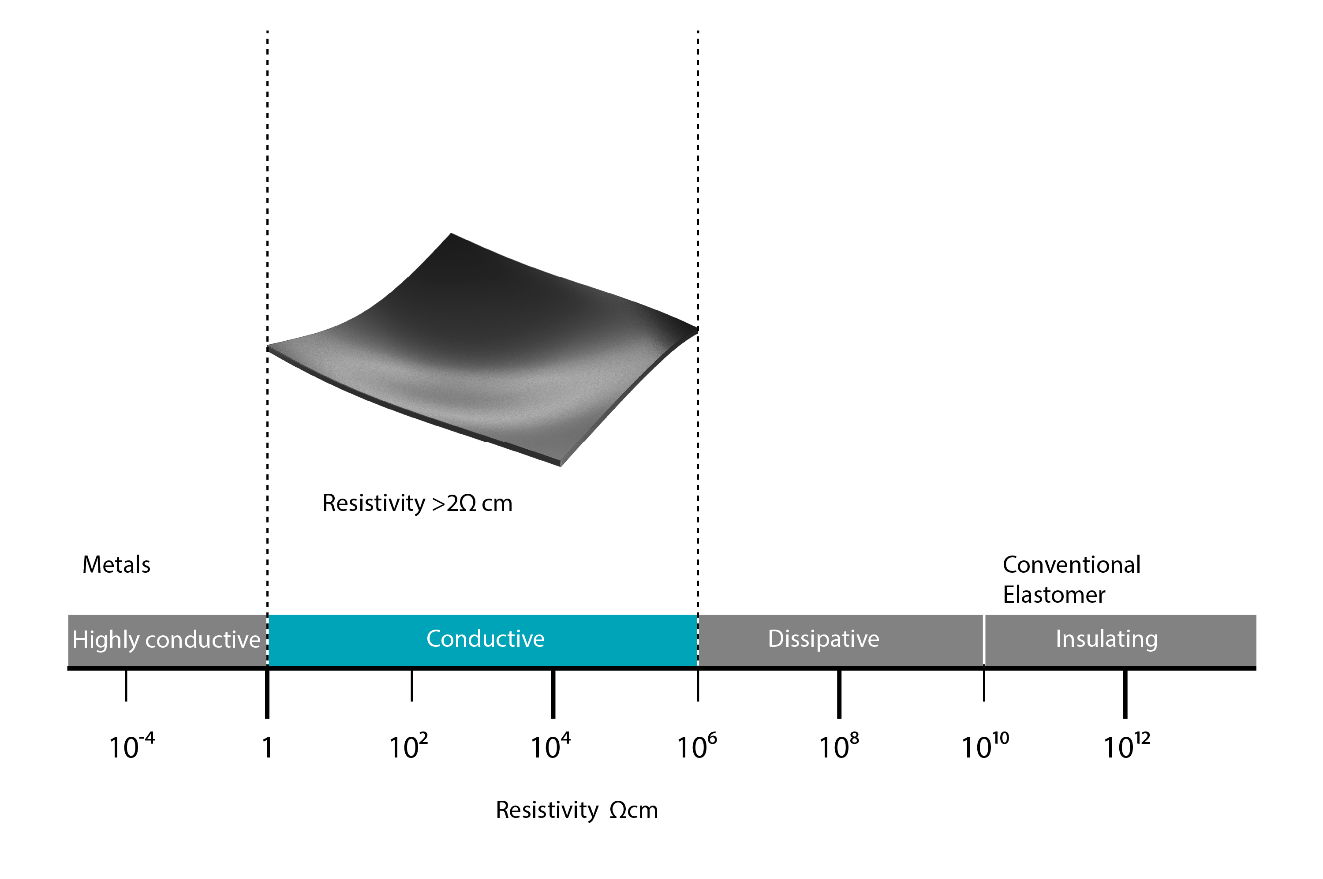

Electrically conductive elastomer is a type of rubber material that has the ability to conduct electricity. This characteristic is unusual for rubber because it is typically a non-conductive material.

Electrically conductive elastomer is composed of a mixture of rubber and conductive particles/fillers that improve its electrical conductivity. The material can be applied in a variety of applications where it can provide electrical grounding and shielding, static discharge, electromagnetic interference (EMI) protection, etc. This new feature of electrical conductivity is added without impacting the standard rubber features such as elasticity, stretchability, robustness, etc. With our developed materials we can achieve a resistivity down to 2Ωcm and at the same time ensure high flexibility and stretchability.

FUNCTIONALITIES

Good damping behavior

Guarantee sealing properties and high system stability even under dynamic applications.

High flexibility

Can be used in a broad range of working conditions (temperature, pressure, chemicals).

Good compression set

The material allows only small deformations in both static and dynamic applications

Lightweight material

Improves the overall environmental impact compared to conventional high-density materials such as metals.

Can be shaped into complex geometries

Provides flexibility in component design and possible combination with other materials (metal, plastic inserts).

High wear and tear resistance

Ensures long service life of the material.

TECHNICAL SPECIFICATIONS

| Properties | Conventional filler (Ref.) | Conductive filler |

|---|---|---|

| Hardness [ShA] | 61 | 70 |

| Tensile strength [N/mm²] | 16 | 13 |

| Modulus 100% [N/mm²] | 2 | 6 |

| Elongation at brake [%] | 450 | 374 |

| Tear resistance [N/mm] | 4 | 10 |

| Compression Set 24h/23°C | 8 | 10 |

| Resistivity [Ωcm] | 1.3E+07 | >2 |

ADDITIONAL INFORMATION

If you want additional information, please check this page:

Datwyler expands material capabilities to support industry shift to e-mobility